Pvdf is a revolutionary coating system that consists of pvdf resin acrylic resin and ceramic pigments giving your panels more vibrant fade resistant durability.

Pvdf metal roof after market coatings.

Kynar polyvinylidene fluoride pvdf resins are used by licensed industrial paint manufacturers in formulating hardy long lasting coatings.

The roofing material is coated in zincalume and other metals to form a barrier that protects the base metal from corrosion.

Pvdf polyvinylidene difluoride is a fluoropolymer resin that is the industry standard for the highest performing paints.

Kynar pvdf coatings for steel aluminum and other metals also have a high dielectric strength excellent resistance to weathering elements in harsh environments.

Kynar pvdf resin based coatings offer long lasting performance in demanding architectural coating applications.

Coatings are applied in factory in coil coating applications for metal roofs garage doors and wall panels or spray applied to formed aluminum extrusions on curtain walls aluminum window and door framing gutters soffits and sunshades.

The pvdf material contains 70 kynar resin which fades slower than other paint resins.

Factory applied pvdf based coatings are used globally and are specified by architects because of their weathering and durability performance.

Home metal roofing fade test pvdf finishes no other paint coating stands up to the sun s harsh uv rays like premium pvdf finishes.

Its photo chemical resistance to ultraviolet light helps prevent breakdown from the sun s rays reducing heat generation and increasing energy efficient coolness.

Cool metal roofs coated with kynar 500 pvdf based resin can reduce energy consumption by up to 40 as part of a total system design as reported by the lawrence berkeley national laboratory.

Factory applied pvdf fluoropolymer resin based coatings protect exposed metal and meet the highest performance standards for coatings on metal.

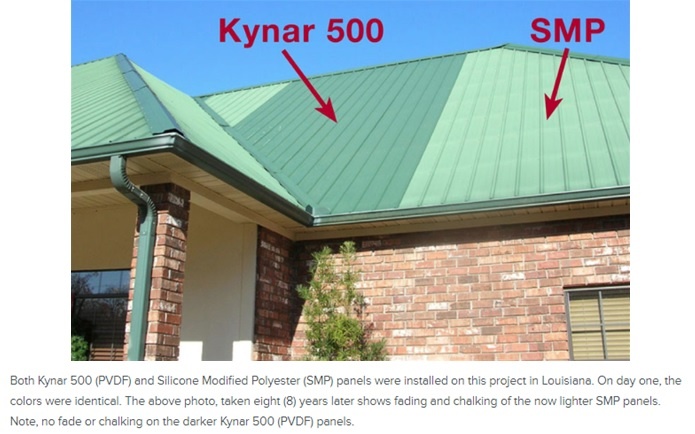

As seen above in less than 10 years the pvdf fade resistance difference is clear.

Fluropon exterior coatings from sherwin williams offer field proven high performance for metal roofing panels and more fluropon containing a 70 percent pvdf proprietary resin system meets or exceeds the american society for testing and materials stringent standards the american architectural manufacturers association s aama 2605 high performance exterior specification.

Pvdf coatings can be applied to metal both before and after forming.

Pvdf coatings are especially resistant to solvents acids and have a very low density compared to similar fluoropolymers.